European standards, certification and patents for mechanical locking

Many mechanical locking manufacturers – including ASSA ABLOY – operate in-house laboratories with testing protocols. Their tests push every device and component to its limit, long before it ever reaches the market. This process is critical to the design and development cycle.

However, stringent third-party testing is also important. An independent mark of quality and durability inspires confidence in an access or security solution: This something a customer must trust to secure their workplace or home, after all.

When specifying a new building, or retrofitting an existing property, compliance is a major component in local and regional building codes. Regulatory approval will depend on installing certified cylinders which meet or exceed agreed standards.

Some certifications simply ensure that information is presented in a consistent, understandable way.

Among these is DIN 18252. It defines terminology, dimensions, requirements, test methods and marking – all to ensure that Euro profile cylinders are standardized and so easily interchangeable and replaceable.

Other standards, however, tell consumers more about the qualities of mechanical devices. These may assess the performance and durability of the cylinder itself, especially when placed under stress or deliberate attack.

Defending the premises: locking strength and resistance

Two critical European standards require an independent assessment of a cylinder or padlock’s build quality and toughness.

EN 1303 for mechanical security covers both cylinders and their keys. It assures performance on criteria including strength, durability and corrosion resistance.

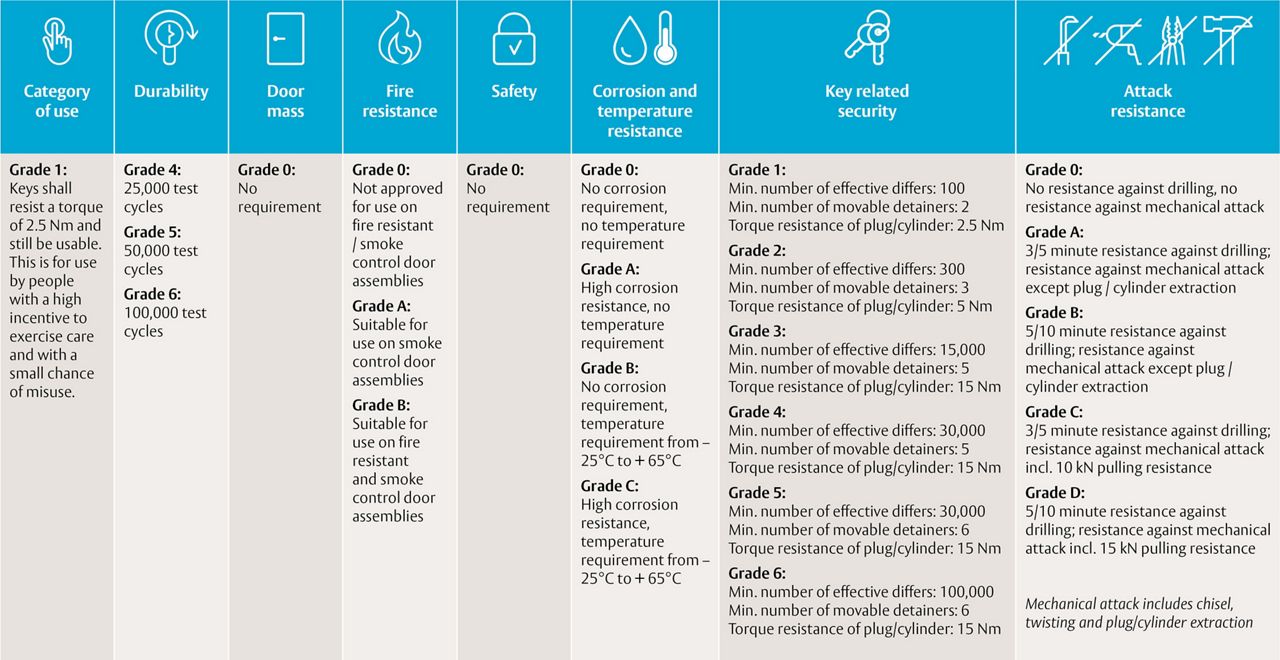

EN 1303 uses an 8-digit coding to report on performance tests. Each digit refers to a product feature measured against the standard’s requirements (see figure, below).

Compliance with EN 1303 doesn’t automatically indicate a high security standard: Precise gradings are decisive. The highest grading a cylinder can achieve is 1-6-0-B-0-6-D; the lowest is 1-4-0-0-0-1-0.

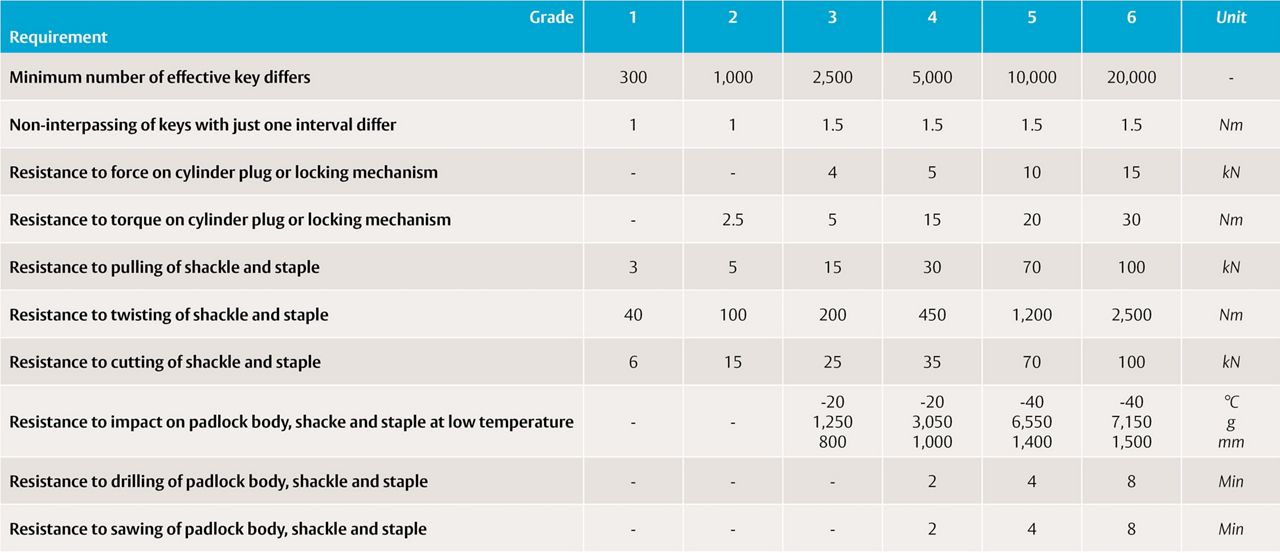

Broadly similar, EN 12320 applies to padlocks, padlock fittings and their keys. It specifies performance requirements and describes test methods for strength, endurance and general operation.

EN 12320 establishes six grades – from grade 1 (low security) to 6 (maximum, only for limited cases) – based on performance tests for corrosion resistance, durability, key-related security and resistance to various forms of attack. To achieve a grade, all its criteria must be met or exceeded.

TS 007 and SKG

Attack resistance is assessed by two further certifications. These are particularly important for cylinders deployed in high-security environments.

Administered by the UK’s Door & Hardware Federation, TS 007 (Technical Standard 007) specifies requirements for cylinders, door handles and other door hardware.

It evaluates locking cylinders’ vulnerability to any attacks which use skill and/or knowledge. A panel of independent locksmiths manually performs picking and bumping tests. EN 1303 attack resistance and key-related security are also considered.

TS 007 assesses high-security cylinders with 1 or 3 stars. TS 007***, the highest, also includes snapping attack resistance.

TS 007 is deployed in conjunction with a British Kitemark certification. The BSI Kitemark confirms testing has been independent and repeated; manufacturing quality is also audited.

SKG ratings are certified by an independent Dutch testing institute and recognized Europe-wide. A cylinder’s SKG rating indicates resistance to common forms of destructive attack and key-related security: similar to EN 1303 but covering additional manipulation types.

The rating is easily identified on the cylinder itself, marked with 2 or 3 stars. SKG***, the highest level, resembles the top EN 1303 grading.

Many insurance providers in the Netherlands make it compulsory for insured houses to have SKG-rated locks.

Why patent protection also matters

Often overlooked, further assurance comes when manufacturers deploy an active patent strategy. Patent protection offers greater control over the distribution and duplication of keys, which adds another layer of security for building owners and users.

Key duplication can be restricted to authorized locksmiths and security partners, which reduces the likelihood of unauthorized key copies in circulation – and hence of unauthorized access to a property.

If cylinder designs are generic or sold with expired patents, the risk grows that valid keys fall into the wrong hands.

Patents help, both by outlawing key copying and by increasing the technical difficulty of producing key blanks.

Leading ASSA ABLOY mechanical locking solutions – including CY100, CY110, CYS10 and CYS00 – offer certified mechanical security and have active patent protection stretching almost into the 2040s.

To get more information, click here to fill out our form.